SMART EVOLUTION

” C’è vero progresso solo quando i vantaggi di una nuova tecnologia diventano per tutti.”

Henry Ford

APPARECCHIATURE DI TEST E CONTROLLO QUALITA’

Progettazione di apparecchiature e software di collaudo per linee di produzione e laboratori di controllo qualità

BIG DATA ANALYTICS

Automazione industriale, raccolta dei dati dal campo, digitalizzazione, monitoraggio e analisi

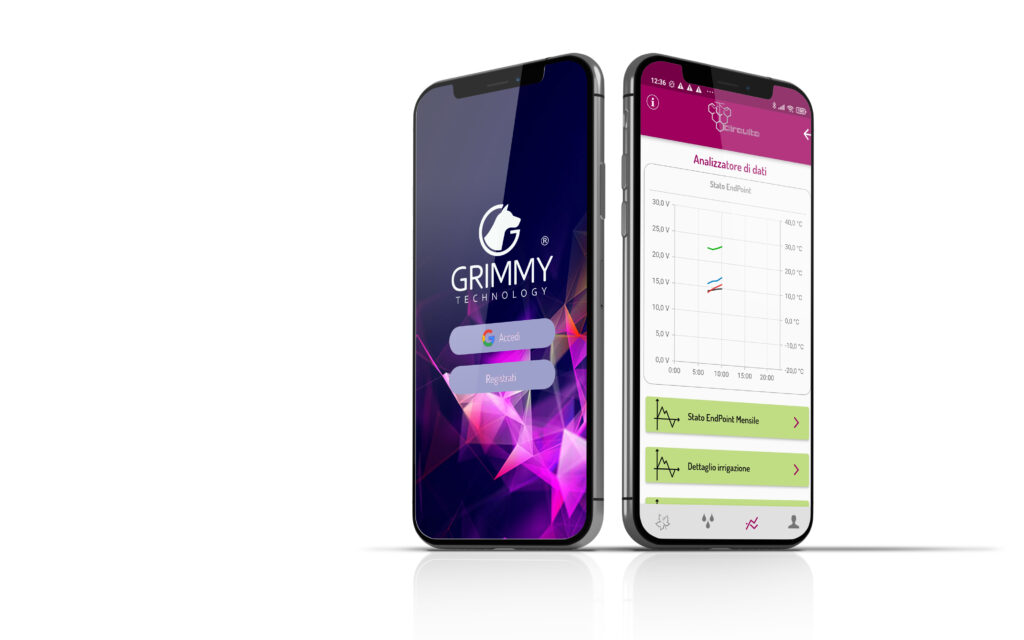

Applicazioni mobile e IoT

Realizziamo App connesse a smart device e ad hardware industriale, utilizzando protocolli standard (es. MQTT, Modbus) o proprietari.

Pillole di “Smart Evolution”

L’APP CHE TI GUIDA NELLE SANIFICAZIONI

GRIMMY® LA NOSTRA SOLUZIONE IOT

Oggetti e luoghi reali interagiscono con il mondo circostante trasferendo dati e informazioni attraverso la rete